When evaluating opportunities for increased greenhouse efficiencies, there are a handful of fairly straightforward options to consider:

Have you been conducting timely maintenance, adding insulation, caulking and various repairs when needed?

Is your lighting customized to maximize your crop growth production?

Are you due for control system, fan, screening or motor upgrades that will minimize wasted energy?

All of these steps are often in the front of mind of greenhouse owners and operators. But what about less tangible operational inefficiencies?

What are Pre-Filled Pots?

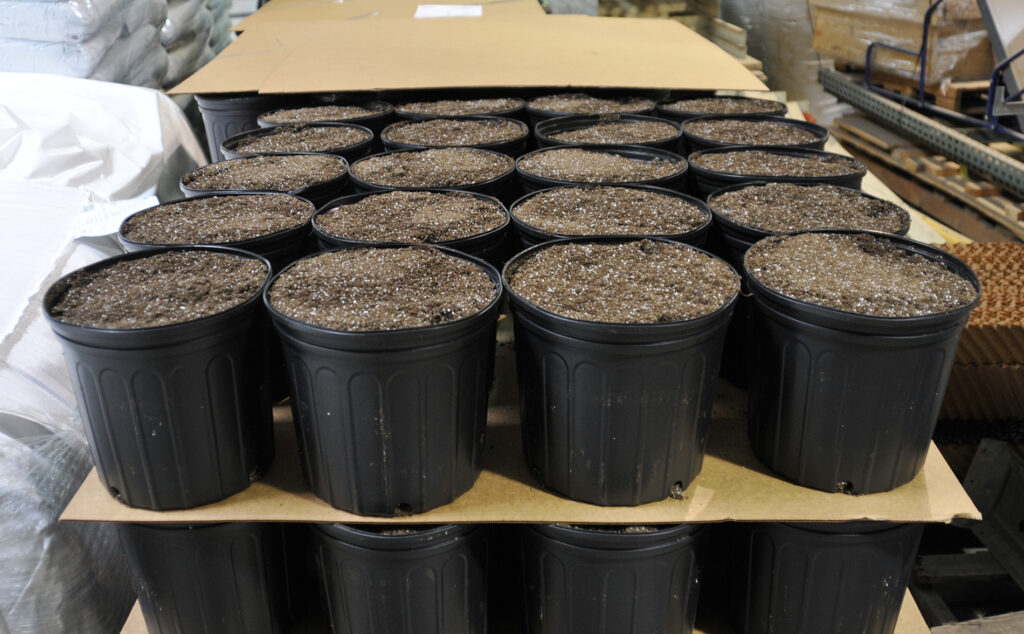

A service that is most commonly utilized by researchers is gaining traction in the corporate greenhouse scene. Pre-filled pots is a service offered that provides the customer with a soil mix that includes amendments, treatments, customized compaction level and container that can be ordered by the pallet and shipped directly to your facility.

What are the Benefits of Pre-Filled Containers?

At its core, pre-filled containers of a soil mixture allow users to reduce overhead in a handful of ways:

Labor via time savings

Repeatability for quality control

Reduction of commodity spend

Labor & Time Savings

For educators and researchers, time is often the most limited and valuable resource available. What is not feasible through budget and staff allocations must be accomplished through existing labor resources, which can result in extra burden amongst the greenhouse team. By outsourcing pot filling, staff free up time through not only the physical act itself, but also by eliminating the purchasing process for soil, fertilizer, plastic pots and more, consolidating to one primary vendor.

Quality through Repeatability

Quality control is a major obstacle when it comes to viable crop outcomes. Is the soil mix consistent with the last, successful batch? Are fertilizer levels optimal? Are your pots filled appropriately? Do you have a record of those previous conditions to ensure repeatability? Consistency through repeatability will reduce the need for crop overproduction to accommodate failure to thrive.

Did you know overproduction is commonly noted operationally as the most expensive waste? And producing/growing more product than you know will be needed is a perfect example of this waste. Pre-filled pots can help minimize this form of waste, freeing up budget better spent in other areas.

Reducing Spend with Commodity Consolidation

When it comes to stocking up for the season, growers are often at the mercy of suppliers and vendors. Prior to their onboarding as pre-filled container users, many of our customers found themselves over purchasing to both account for current supply chain concerns as well as simply working around the volumes offered and available for purchase.

If you only need X amount of soil, but have to purchase a higher amount of Y because that is how it is sold, the difference in cost is money tied up in inventory that may expire before it is able to be utilized. With pre-filled containers, users pay for exactly what is needed, not more and not less, and their supplier manages any inventory constraints that may exist.

Filling Your Growing Needs

All of these result in a reduction of overhead through streamlined operations through effective labor and time utilization, increased quality and commodity efficiency. Plant Growth Logistics & Services, a division of Hummert, offers a wide arrangement of soil mixes, amendments, treatments, compaction levels, and containers that can be ordered by the pallet and shipped to your facility, ready to use. Prepared by a dedicated staff that follows systematic operating procedures to ensure consistency and quality with every order.

Want to learn more? Please complete this information for a pre-filled container consultation.